When it comes to components that quietly power some of the world’s most robust industrial machines, spherical roller bearings are unsung heroes. These powerful bearings are designed for one thing—extreme durability under pressure. Whether you’re dealing with mining crushers, paper mills, or marine gearboxes, this bearing type plays a vital role in keeping machinery running smoothly.

In this guide, we’ll break down what spherical roller bearings are, explore their key advantages, highlight real-world applications, and show how Veermani delivers precision-engineered bearing solutions that industries can rely on.

What Exactly Are Spherical Roller Bearings?

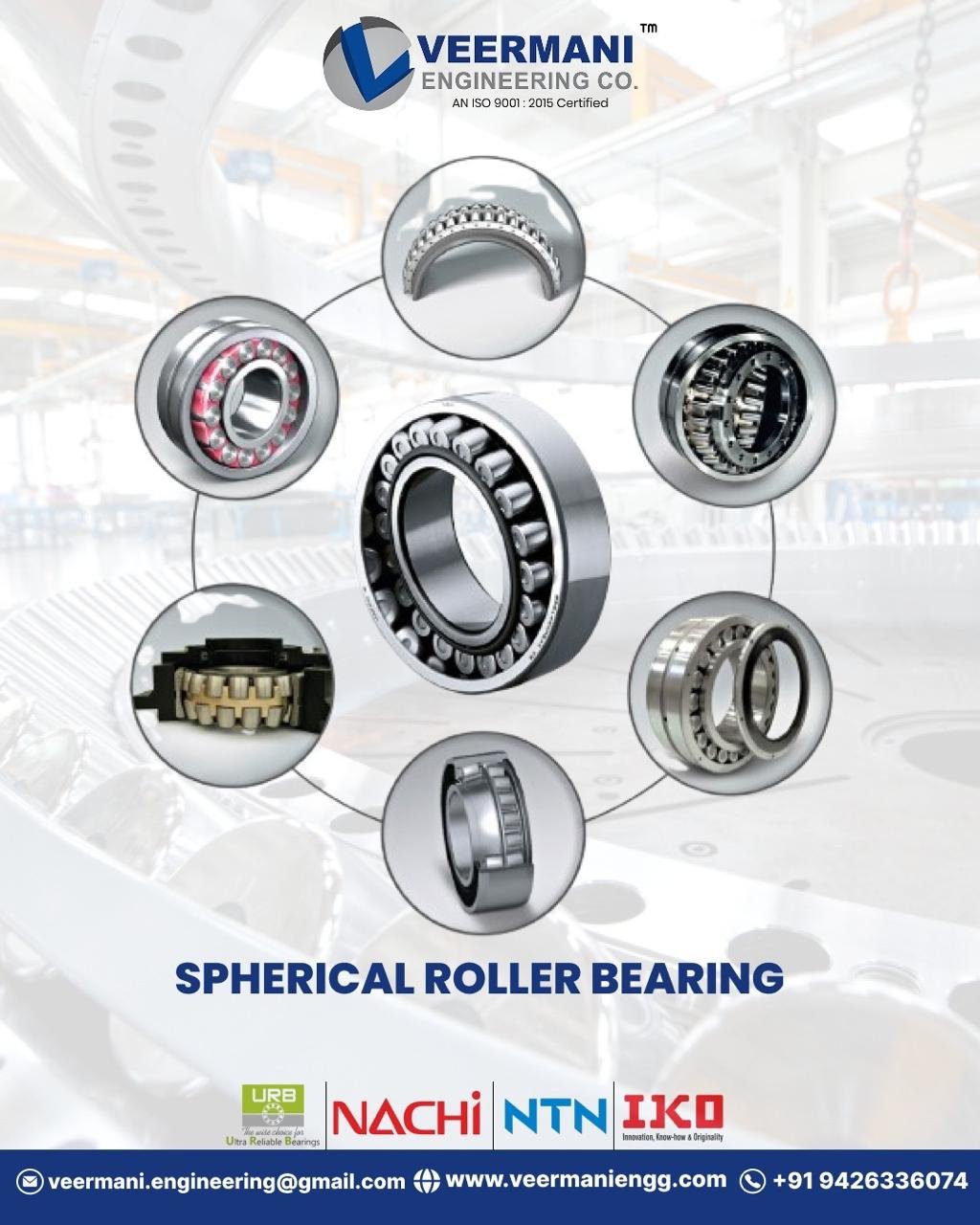

A spherical roller bearing is a rolling-element bearing that accommodates misalignment and heavy loads with ease. It consists of an outer ring with a spherical raceway, an inner ring with two raceways inclined at an angle, and two rows of rollers.

What makes them different?

• Self-Aligning Capability: The rollers are barrel-shaped and align automatically, making them ideal for situations where shaft deflection or misalignment is common.

• Heavy Load Handling: These bearings are designed to carry both radial and axial loads simultaneously—even under harsh operating conditions.

This unique combination makes spherical roller bearings especially suited for applications that involve heavy machinery, continuous movement, and minimal downtime.

Key Benefits of Spherical Roller Bearings

So, why are spherical roller bearings the go-to choice in many demanding industries? Here are the key benefits:

1. Excellent Load-Bearing Capacity

The two-row roller design allows for superior load distribution, enabling the bearing to handle both high radial and axial forces effectively.

2. Compensation for Misalignment

Even if the shaft is not perfectly aligned with the housing, these bearings continue to perform without causing excessive wear or failure.

3. Enhanced Durability

Thanks to their robust design, spherical roller bearings last longer and require less frequent replacements—making them cost-effective in the long run.

4. Resistance to Shock and Vibration

Their ability to absorb shock loads makes them ideal for industries such as mining, steel, and cement, where machines are subject to constant vibrations.

5. Low Maintenance Requirements

Advanced designs often incorporate self-lubricating features or sealed enclosures that minimize upkeep and prolong service life.

Applications of Spherical Roller Bearings

Let’s explore where you’ll typically find these bearings in action.

1. Mining and Quarrying

Heavy equipment like crushers, vibrating screens, and conveyor belts use spherical roller bearings to handle dust, high loads, and impact forces.

2. Paper and Pulp Industry

Machines such as paper rollers and dryers need bearings that can tolerate misalignment and operate at high speeds. These bearings are perfect for the job.

3. Power Generation

Turbines, generators, and gearboxes in power plants rely on the consistent performance of spherical roller bearings to reduce downtime.

4. Steel and Metal Processing

In steel mills, where machinery undergoes constant thermal expansion and shock loads, these bearings provide the needed resilience.

5. Marine and Offshore Equipment

Marine propulsion systems, winches, and lifting equipment often operate in corrosive environments. Sealed versions of spherical roller bearings help protect against water ingress and wear.

Why Choose Veermani for Spherical Roller Bearings?

At Veermani Engineering, we don’t just produce bearings—we deliver reliability. Our commitment to precision engineering and material excellence makes us a trusted partner in demanding industrial sectors.

Precision Manufacturing

Every spherical roller bearing we produce is crafted using premium-grade steel, CNC machining, and heat-treatment processes to ensure durability and dimensional accuracy.

Tailored Solutions

No two applications are exactly alike. That’s why we offer custom sizes, cages, lubrication options, and sealing configurations to suit your specific operating conditions.

End-to-End Support

From helping you choose the right model to offering post-installation support, Veermani is with you at every step.

Choosing the Right Spherical Roller Bearing

Before selecting a spherical roller bearing, it’s essential to assess the following:

• Load Type and Direction: Is it mainly radial, axial, or both?

• Operating Environment: Will it face dust, moisture, or extreme temperatures?

• Speed and Vibration Levels: How fast will the shaft rotate, and is it subject to continuous shocks?

• Maintenance Access: Do you prefer sealed-for-life or re-lubrication designs?

If you’re uncertain, our technical team at Veermani Engineering is always ready to help guide you toward the right solution.

Final Thoughts

Spherical roller bearings may seem like simple mechanical components, but their role in the smooth functioning of industrial machinery is crucial. Their unique design, ability to handle extreme conditions, and self-aligning capability make them an indispensable part of heavy-duty equipment across industries.